Cheese Triumph, or Why Everything is Going Like Clockwork for Belarusian Cheesemakers

Photo by the Ministry of Agriculture News of the topic Are there any of you who love cheese and cannot imagine your diet without mozzarella, camembert or parmesan? Today is the day of those who answer this question positively - cheese gourmets, connoisseurs of cheese making and just fans of the popular product. A huge assortment, and according to various estimates, from 800 to 2 thousand varieties of cheese are produced in the world, allows everyone to choose their favorites: cheddar, feta, ricotta, gouda, brie, gorgonzola, stilton or still Roquefort? And choosing one from a long list is not an easy task, because cheese is not only tasty, but also economically profitable, which is known firsthand in Belarus. it is not for nothing that we produce multiple volumes of cheeses than our partners in the EAEU , and firmly hold the fourth position in cheese exports in the world, behind only the EU , the usa and New Zealand. In honor of the World Cheese Lovers' Day, celebrated on 20 January, a BELTA correspondent studied the "cheese plate" of Belarusians and tried to compile a formula for the success of domestic cheesemakers.

The question "Why are Belarus and other competing countries showing increased interest in cheese making?" is quite justified. According to expert forecasts, in the next decade, sales of all types of cheese in the world will increase by $55 billion, which is why larger players in the market are trying to secure a piece of this pie in advance. Belarusian cheesemaking is already actively expanding its range, trying new packaging, and using fresh packaging solutions. Since cheese is one of the main export-oriented vectors of the dairy industry and the entire agricultural sector of the republic, producers are keeping their nose to the wind.

The most "cheese" region of Belarus is Brest

"Our cheeses have found their niche in the world market. In addition to the fact that we are one of the main suppliers of this type of food to foreign markets, the republic fully provides itself with cheeses and significantly surpasses other CIS countries in cheese production per capita," said Maria Klimova, Deputy HEAD of the Main Directorate of Processing Industry of the Ministry of Agriculture and Food. "For comparison, Armenia produces 8.2 kg of cheese per person, RUSSIA - 4.6 kg, Kazakhstan and Kyrgyzstan - 0.8 kg each. According to the EEC, Belarus has reached a level of 29.9 kg."

This is the case when the numbers speak for themselves, and our country, meanwhile, continues to increase cheese production: new types appear, cheese-making lines are modernized and technically re-equipped.

According to statistics from the Ministry of Agriculture and Food, 28 enterprises (excluding branches) are engaged in cheese production in Belarus, including 22 MILK processing organizations of the ministerial system. In 2024In 2018, they processed 32% of the milk produced in the country into cheeses and manufactured over 325 thousand tons of products, which is 9% more than in 2023. In regional terms, the largest volumes of cheese are produced in the Brest region (39.8%).

For every day, for connoisseurs of delights and adherents of a healthy lifestyle

The amount of cheese produced in the country will grow, there is no doubt about it, but the important thing is that the volumes do not affect the quality. Experienced cheesemakers even compare their skills with art. Historically, the best in cheese making are Europeans. The Swiss and Dutch, Italians and French, Greeks and Germans continue to create unique cheese varieties, protecting the culture of production of this product at the legislative level. Belarusians are not lagging behind the general trend. The republic produces about 485 types of cheese, of which more than 60 are hard and aged, including 7 types of year-old cheese, 33 with fillers and 4 with blue mold. Hard and semi-hard cheeses, which account for about 88% of the total production volume, remain a traditional item of our EXPORT shipments.

"In recent years, we have managed to significantly expand the range of premium hard and aged cheeses," comments Maria Klimova. "The most popular with consumers are traditional semi-hard cheeses, namely "Rossiysky", "Gollandsky", "Poshekhonsky", so semi-hard cheeses are produced in the largest volume. The range in this category is expanding in Verkhnedvinsk, Novogrudok, Postavy, where analogues of the famous Dutch Gouda cheeses are produced. German Tilsiter cheeses have been learned to be made in Kobrin and Oshmyany, and the group of Italian cheeses Provoletta, Scamorza, Provola have been mastered in Turov." And what kind of fillings and spices you won't taste in Belarusian cheeses! There are some with truffles, chanterelles, fenugreek, basil, wild garlic, caraway, paprika, pepper and garlic, pumpkin seeds, with the aroma of baked milk, caramel, honey, walnuts... The list can go on. Cheese makers also follow fashion trends. Who hasn't heard of healthy eating? With the growing consumer interest in low-fat cheeses, where the mass fraction of fat fluctuates from 20% to 35%, such products have been learned to be prepared in Oshmyany, Rogachev, Grodno.

Finally, domestic cheese makers have conquered the positions of the "golden fund" - cheeses using propionic acid bacteria, like the Dutch Maasdam. Such production is the highest level of skill, and in Belarus it has been launched at more than one site: in Kobrin, Verkhnedvinsk, Novogrudok, Postavy, Rogachev, Slutsk, Berestovitsa and Shchuchin.

"The peculiarity of the cheese is that the starter contains propionic acidbacteria , so the cheese has a wonderful pattern of round large cheese eyes and a spicy-sweet taste, - explained the deputy head of the main department of the processing industry. - I will note that the development of such types of cheese is a kind of indicator of the high level of development of the dairy industry and agriculture, since they are quite capricious in technology. In addition, such cheeses cannot be made without high-quality dairy raw materials. Without a doubt, we will increase their production in the country."

No worse than the Swiss docks

Each enterprise stands out among similar ones by its specialization. Experts even associate a certain name of cheese with the plant for which it has become a brand. Let's visit, for example, the Kobrin butter and CHEESE FACTORY, which produces a special aged cheese that has no analogues not only on the Belarusian market, but also on the Russian market - Swiss raclette. For its production, the enterprise was equipped with special ripening chambers equipped with technology to maintain the required temperature, humidity and ammonia level, and other equipment was purchased. The chief technologist of the plant, Snezhanna Kuzmenya, promises to introduce the production process in detail.

"The process of making raclette is very complex technologically. Let's start with the fact that even the highest quality milk is not enough to produce this cheese - it must be specially suitable for cheese. Only with such raw materials can you make cheese that is not inferior to the best European samples. We were able to bring the quality of our milk to the required level, - the chief technologist shares the nuances. - A distinctive feature of production is the natural ripening of cheese with the participation of surface microflora. It is the long ripening in the created conditions and the method of processing that determine the technology of raclette. This complex process requires special knowledge and extremely strict adherence to sanitary standards."

The cheese matures for three months, which, according to experts, allows it to "open up." Gourmets can probably detect notes of mushrooms and fruits in the creamy taste, and cheese sommeliers will recommend using it for melting.

Belarus is scaling up the production of soft cheeses, including moldy ones

. But the "cheese plate" of Belarusians is not limited to hard and semi-hard varieties. The country is also rapidly increasing the production of soft cheeses, the share of which in the total volume already exceeds 10%. They are made in different ways: salty, sweet, spicy, with spices, all kinds of acidity, fat content and form. Enterprises of the Gomel and MINSK regions, leaders in the production of soft cheeses in the republic, are significantly expanding their range, giving preference to Italian technologies: mozzarella, ricotta, mascarpone, made in Belarusian, are probably familiar to many. New soft cheese production facilities have been introduced cheeses from enterprises of the Vitebsk and Grodno regions.

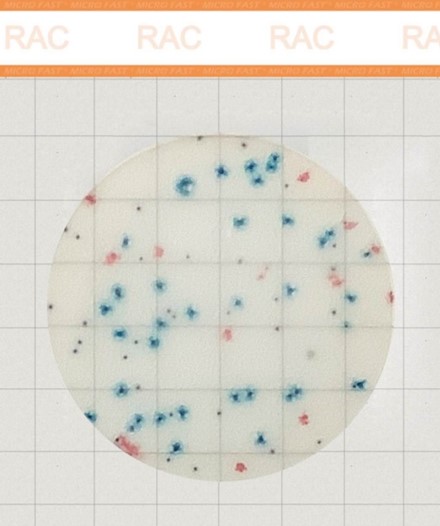

Cheeses with noble mold deserve special attention, the production of which at the initial stages seems like a difficult task. First of all, due to technical aspects: such cheeses are made in an isolated area, and the use of mold is unacceptable to combine with the production of other dairy products. In short, there are many nuances, but domestic cheesemakers are ready to cope even with them. Moreover, Belarusian scientists from the Institute of MEAT and Dairy Industry of the National Academy of Sciences help with the technology.

"We have already mastered such production. Cheeses with blue mold are produced in Naroch. In 2024, the main production building was reconstructed with the modernization of the line for the production of cheeses with blue mold, which made it possible to double the capacity. Last year was remembered for another important project in the same direction: a new production facility for the production of cheeses with white mold began operating in Vileika," recalls the deputy head of the main department of the processing industry of the Ministry of Agriculture.

Pickled cheeses - feta and brine - are popular among buyers. Belarusian producers are proud of their quality, as well as the quality of other cheeses.

According to one principle

And here we are already in Lida. The local dairy and canning plant produces several varieties of soft cheeses, which have significant differences in production technology. For example, fermented milk is made from buttermilk obtained by fermentation during the production of butter using bacterial starters, and the famous "Adygei" does not ripen at all, it is made from pasteurized milk by thermo-acid coagulation (curdling) of the milk protein contained in it. The leading technologist of the enterprise Svetlana Nosevich helps to understand all the intricacies of production.

"Soft cheeses have a common technological process, which includes a number of operations," the technologist explains. "The first stage is acceptance, cleaning, normalization, pasteurization and cooling of raw materials, the second is fermentation and souring of the mixture. The next step, if necessary, is thermal-acid coagulation of milk protein. Then comes the processing of the curd, its formation and self-pressing, after which we proceed to pressing the cheese and its salting, if we prepare salted soft cheeses, packaging and cooling."

Belarusian cheese is known and loved on both sides of the globe . Gradually, Belarusian cheesemakers realize that cow's milk is not the only thing, and they begin to use goat and sheep

milk

in making cheese . Farmers are also actively joining this process. True, the raw materials of goat and sheep milk do not allow it to be used on an industrial scale, which, however, did not prevent cheesemakers of Mstislavl from producing experimental batches of cheeses from a mixture of cow and goat milk. According to a representative of the Ministry of Agriculture, these cheeses are currently maturing.

In general, cheese consumption in the republic is growing steadily. And in the world, if we believe the experts' forecasts, there is a positive trend that will continue in the future. Belarus only benefits from this, increasingly diversifying its exports . If in 2023, domestic cheese makers shipped their products to 23 countries, then in 2024 they already made deliveries to 29 countries. In some of them, export volumes were increased: Azerbaijan , Kazakhstan, Russia, Tajikistan, Uzbekistan - and this is only in the CIS, and outside it, the list includes much more unexpected buyers with growing appetites.

One way or another, experts have reason to believe that the number of such will grow. After all, this is ultimately the goal of the ambitious tasks in the field of cheese making for the next five years: the emergence of new and an increase in existing cheese production capacities, expansion of the range and the search for fresh ideas and packaging solutions, and most importantly - maintaining the quality bar at the same high level. For Belarusians - familiar.

Vera VASILEVSKAYA, BELTA.

The question "Why are Belarus and other competing countries showing increased interest in cheese making?" is quite justified. According to expert forecasts, in the next decade, sales of all types of cheese in the world will increase by $55 billion, which is why larger players in the market are trying to secure a piece of this pie in advance. Belarusian cheesemaking is already actively expanding its range, trying new packaging, and using fresh packaging solutions. Since cheese is one of the main export-oriented vectors of the dairy industry and the entire agricultural sector of the republic, producers are keeping their nose to the wind.

The most "cheese" region of Belarus is Brest

"Our cheeses have found their niche in the world market. In addition to the fact that we are one of the main suppliers of this type of food to foreign markets, the republic fully provides itself with cheeses and significantly surpasses other CIS countries in cheese production per capita," said Maria Klimova, Deputy HEAD of the Main Directorate of Processing Industry of the Ministry of Agriculture and Food. "For comparison, Armenia produces 8.2 kg of cheese per person, RUSSIA - 4.6 kg, Kazakhstan and Kyrgyzstan - 0.8 kg each. According to the EEC, Belarus has reached a level of 29.9 kg."

This is the case when the numbers speak for themselves, and our country, meanwhile, continues to increase cheese production: new types appear, cheese-making lines are modernized and technically re-equipped.

According to statistics from the Ministry of Agriculture and Food, 28 enterprises (excluding branches) are engaged in cheese production in Belarus, including 22 MILK processing organizations of the ministerial system. In 2024In 2018, they processed 32% of the milk produced in the country into cheeses and manufactured over 325 thousand tons of products, which is 9% more than in 2023. In regional terms, the largest volumes of cheese are produced in the Brest region (39.8%).

For every day, for connoisseurs of delights and adherents of a healthy lifestyle

The amount of cheese produced in the country will grow, there is no doubt about it, but the important thing is that the volumes do not affect the quality. Experienced cheesemakers even compare their skills with art. Historically, the best in cheese making are Europeans. The Swiss and Dutch, Italians and French, Greeks and Germans continue to create unique cheese varieties, protecting the culture of production of this product at the legislative level. Belarusians are not lagging behind the general trend. The republic produces about 485 types of cheese, of which more than 60 are hard and aged, including 7 types of year-old cheese, 33 with fillers and 4 with blue mold. Hard and semi-hard cheeses, which account for about 88% of the total production volume, remain a traditional item of our EXPORT shipments.

"In recent years, we have managed to significantly expand the range of premium hard and aged cheeses," comments Maria Klimova. "The most popular with consumers are traditional semi-hard cheeses, namely "Rossiysky", "Gollandsky", "Poshekhonsky", so semi-hard cheeses are produced in the largest volume. The range in this category is expanding in Verkhnedvinsk, Novogrudok, Postavy, where analogues of the famous Dutch Gouda cheeses are produced. German Tilsiter cheeses have been learned to be made in Kobrin and Oshmyany, and the group of Italian cheeses Provoletta, Scamorza, Provola have been mastered in Turov." And what kind of fillings and spices you won't taste in Belarusian cheeses! There are some with truffles, chanterelles, fenugreek, basil, wild garlic, caraway, paprika, pepper and garlic, pumpkin seeds, with the aroma of baked milk, caramel, honey, walnuts... The list can go on. Cheese makers also follow fashion trends. Who hasn't heard of healthy eating? With the growing consumer interest in low-fat cheeses, where the mass fraction of fat fluctuates from 20% to 35%, such products have been learned to be prepared in Oshmyany, Rogachev, Grodno.

Finally, domestic cheese makers have conquered the positions of the "golden fund" - cheeses using propionic acid bacteria, like the Dutch Maasdam. Such production is the highest level of skill, and in Belarus it has been launched at more than one site: in Kobrin, Verkhnedvinsk, Novogrudok, Postavy, Rogachev, Slutsk, Berestovitsa and Shchuchin.

"The peculiarity of the cheese is that the starter contains propionic acidbacteria , so the cheese has a wonderful pattern of round large cheese eyes and a spicy-sweet taste, - explained the deputy head of the main department of the processing industry. - I will note that the development of such types of cheese is a kind of indicator of the high level of development of the dairy industry and agriculture, since they are quite capricious in technology. In addition, such cheeses cannot be made without high-quality dairy raw materials. Without a doubt, we will increase their production in the country."

No worse than the Swiss docks

Each enterprise stands out among similar ones by its specialization. Experts even associate a certain name of cheese with the plant for which it has become a brand. Let's visit, for example, the Kobrin butter and CHEESE FACTORY, which produces a special aged cheese that has no analogues not only on the Belarusian market, but also on the Russian market - Swiss raclette. For its production, the enterprise was equipped with special ripening chambers equipped with technology to maintain the required temperature, humidity and ammonia level, and other equipment was purchased. The chief technologist of the plant, Snezhanna Kuzmenya, promises to introduce the production process in detail.

"The process of making raclette is very complex technologically. Let's start with the fact that even the highest quality milk is not enough to produce this cheese - it must be specially suitable for cheese. Only with such raw materials can you make cheese that is not inferior to the best European samples. We were able to bring the quality of our milk to the required level, - the chief technologist shares the nuances. - A distinctive feature of production is the natural ripening of cheese with the participation of surface microflora. It is the long ripening in the created conditions and the method of processing that determine the technology of raclette. This complex process requires special knowledge and extremely strict adherence to sanitary standards."

The cheese matures for three months, which, according to experts, allows it to "open up." Gourmets can probably detect notes of mushrooms and fruits in the creamy taste, and cheese sommeliers will recommend using it for melting.

Belarus is scaling up the production of soft cheeses, including moldy ones

. But the "cheese plate" of Belarusians is not limited to hard and semi-hard varieties. The country is also rapidly increasing the production of soft cheeses, the share of which in the total volume already exceeds 10%. They are made in different ways: salty, sweet, spicy, with spices, all kinds of acidity, fat content and form. Enterprises of the Gomel and MINSK regions, leaders in the production of soft cheeses in the republic, are significantly expanding their range, giving preference to Italian technologies: mozzarella, ricotta, mascarpone, made in Belarusian, are probably familiar to many. New soft cheese production facilities have been introduced cheeses from enterprises of the Vitebsk and Grodno regions.

Cheeses with noble mold deserve special attention, the production of which at the initial stages seems like a difficult task. First of all, due to technical aspects: such cheeses are made in an isolated area, and the use of mold is unacceptable to combine with the production of other dairy products. In short, there are many nuances, but domestic cheesemakers are ready to cope even with them. Moreover, Belarusian scientists from the Institute of MEAT and Dairy Industry of the National Academy of Sciences help with the technology.

"We have already mastered such production. Cheeses with blue mold are produced in Naroch. In 2024, the main production building was reconstructed with the modernization of the line for the production of cheeses with blue mold, which made it possible to double the capacity. Last year was remembered for another important project in the same direction: a new production facility for the production of cheeses with white mold began operating in Vileika," recalls the deputy head of the main department of the processing industry of the Ministry of Agriculture.

Pickled cheeses - feta and brine - are popular among buyers. Belarusian producers are proud of their quality, as well as the quality of other cheeses.

According to one principle

And here we are already in Lida. The local dairy and canning plant produces several varieties of soft cheeses, which have significant differences in production technology. For example, fermented milk is made from buttermilk obtained by fermentation during the production of butter using bacterial starters, and the famous "Adygei" does not ripen at all, it is made from pasteurized milk by thermo-acid coagulation (curdling) of the milk protein contained in it. The leading technologist of the enterprise Svetlana Nosevich helps to understand all the intricacies of production.

"Soft cheeses have a common technological process, which includes a number of operations," the technologist explains. "The first stage is acceptance, cleaning, normalization, pasteurization and cooling of raw materials, the second is fermentation and souring of the mixture. The next step, if necessary, is thermal-acid coagulation of milk protein. Then comes the processing of the curd, its formation and self-pressing, after which we proceed to pressing the cheese and its salting, if we prepare salted soft cheeses, packaging and cooling."

Belarusian cheese is known and loved on both sides of the globe . Gradually, Belarusian cheesemakers realize that cow's milk is not the only thing, and they begin to use goat and sheep

milk

in making cheese . Farmers are also actively joining this process. True, the raw materials of goat and sheep milk do not allow it to be used on an industrial scale, which, however, did not prevent cheesemakers of Mstislavl from producing experimental batches of cheeses from a mixture of cow and goat milk. According to a representative of the Ministry of Agriculture, these cheeses are currently maturing.

In general, cheese consumption in the republic is growing steadily. And in the world, if we believe the experts' forecasts, there is a positive trend that will continue in the future. Belarus only benefits from this, increasingly diversifying its exports . If in 2023, domestic cheese makers shipped their products to 23 countries, then in 2024 they already made deliveries to 29 countries. In some of them, export volumes were increased: Azerbaijan , Kazakhstan, Russia, Tajikistan, Uzbekistan - and this is only in the CIS, and outside it, the list includes much more unexpected buyers with growing appetites.

One way or another, experts have reason to believe that the number of such will grow. After all, this is ultimately the goal of the ambitious tasks in the field of cheese making for the next five years: the emergence of new and an increase in existing cheese production capacities, expansion of the range and the search for fresh ideas and packaging solutions, and most importantly - maintaining the quality bar at the same high level. For Belarusians - familiar.

Vera VASILEVSKAYA, BELTA.