District-scale project: new pharmaceutical manufacturing plant in Nesvizh to produce up to 30 types of drugs

A modern plant for the production of medical products and a new scale of packaging production: in the Nesvizh district, the "" initiative is already yielding tangible results.

Fish look for deeper waters, and business looks for more profitable, simpler and more reliable ones. This formula is what is prompting more and more enterprises of various forms of ownership across the country to rely on the "One District - One Project" initiative. The advantages are obvious to everyone: a low percentage of a bank loan in Belarusian rubles, and as a result - a quick payback of the investment project. The return for the regions is also obvious: new jobs, competitive salaries, tax revenues to the local budget.

BELTA correspondents learned about the significant results that the implementation of the initiative has already yielded in the Nesvizh District .

Local action tablet

it is simply impossible not to notice the new production building of the Foreign Unitary Enterprise "Med-Interplast" in Nesvizh. The four-story plant for the production of pharmaceuticals on Leninskaya Street, shining in the sun, attracts attention with its stylish design and modern finishing materials of the facade. Chic, shine, cleanliness! It is hard to believe that this large-scale project - from the idea and development of the architectural project to its implementation - was completed in just over two years.

Before entering the production facilities, together with the DIRECTOR of Med-Interplast, Andrey Trizonov, we go through all the stages of preliminary personnel training: we treat our hands with disinfectants and put on disposable protective clothing.

- To be honest, the idea to participate in the initiative was suggested to us by the district executive committee. The company has been on the Belarusian market since 2009. The main production facilities are located in Nesvizh, where we produce toilet and laundry soap, as well as mustard bags made of non-woven materials. Later, in 2013, we launched the production of vitamin preparations, medicines with hepatoprotective, neuroprotective, cardiological and other effects (we produce about 2.8 million packages per year). The business has been developing successfully all these years, so our foreign founders thought about expanding the enterprise, - says Andrey Trizonov. - The business plan for the construction of a full-cycle production was first presented and reviewed by the Nesvizh District Executive Committee, then approved in the region and eventually received financing from the Development Bank. The total cost of the facility is 27.5 million rubles (10 million rubles were provided as a loan, another 17.5 million were our own funds). Construction began in January 2023, and the plant was commissioned in February 2025. Now, the production of drugs here will be organized from A to Z: starting with the stage of drug development, obtaining the finished mixture - to the final product in the form of tablets, capsules or sachets.

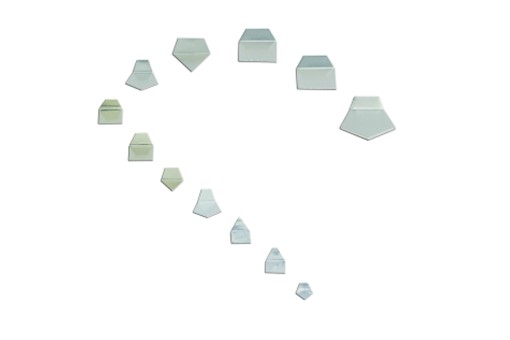

The plant has equipment from leading European and Chinese manufacturers. We witnessed its fine-tuning, adjustment and production of a pilot batch of finished products. The next stage is technology transfer: transfer of registered drugs to a new site. This autumn, industrial production of drugs is expected to begin here.

- We will produce tablets, capsules, and capsules with herbal medicinal raw materials - about 30 items in total. We are talking primarily about drugs for the treatment of diseases of the NERVOUS SYSTEM, digestive tract, musculoskeletal and cardiovascular systems, as well as antimicrobial drugs and for the treatment of diseases of the urogenital organs, - Andrey Trizonov shows the production lines. - Today, 17 new specialists are already working here. In the next couple of years, when we reach the design capacity, we will hire another 58 people. The salary for personnel is higher than the average for the district, it is quite competitive and allows us to select the qualified specialists needed for production. And not only from Nesvizh, but also from neighboring districts. Our HR department has felt the demand - many want to work at a new modern enterprise with a good social package.

Finished medical products are almost entirely oriented towards the domestic market: 90% of medicines will be sold here. The remaining 10% are planned to be exported to RUSSIA, Kazakhstan , Uzbekistan , Azerbaijan , Armenia and Georgia - all logistics chains have already been built. The main focus of Med-Interplast at this stage is the production of high-quality import-substituting drugs for Belarus, such as top-notch ones as Neurocholine for recovery after a stroke.

- We pay special attention to quality: active substances from which the drugs are produced are purchased from leading manufacturers in India, CHINA, Germany. Already this fall, if everything goes as planned, the plant will produce 300 thousand packages of tablets per month. In the near future, we want to increase production volumes to 700 thousand packages per month, - the director shares his plans .

Andrey Trizonov especially emphasizes: the "One District - One Project" initiative is an effective mechanism for supporting local businesses. In the case of "Med-Interplast", it will allow the domestic market to be provided with high-quality, affordable medicines in a short time, new jobs will be created, and the country's EXPORT potential will be expanded.

"8.5% per annum for 10 years - very favorable conditions, such offers are simply not available today! We are grateful that 40% of the cost of construction and equipment of the new plant was financed by the Development Bank: this will allow us to reach the full production cycle much faster and make the final product more competitive," Andrey Trizonov names the obvious advantages. "I am confident that ultimately we will be able to reduce the five-year payback period of our project according to the approved business plan. All necessary conditions have been created for this."

Beautifully packaged - successfully sold

The next story is also about business activity and growth, when the state lends a shoulder at the right and important moment.

IOOO "Flexoservice" does not need any special introduction, not only in Belarus, but also in the CIS. The company is rightfully considered one of the leaders in the segment of production of paper bags for food products with a capacity of 0.5-5 kg. To put it simply, almost every bag of SUGAR that you see in the store is made in Nesvizh. And here they also produce paper packaging for SALT, tea,coffee , fast food - millions of paper bags per month.

- Our company has been on the market since 2002. We have focused on the highly specialized production of sugar and FLOUR bags with a capacity of 0.5 to 5 kg. Trends of recent years: competition on the shelf for the buyer (especially for sugar and flour) is conducted mainly through marketing, and the quality of the packaging plays a significant role in this. Therefore, customer requirements for the packaging manufacturer and its appearance have increased many times over, - they say at the enterprise. - Taking this into account, the average print run has decreased, the time required by the client for manufacturing the packaging has decreased, the number of colors in the layouts has increased, and the layouts themselves have become more complex. This is why the quality of printing and prepress equipment is now coming to the forefront.

The enterprise currently operates 9 lines for the production of bags, which are serviced by about 60 people. The production capacity of the enterprise is about 36 million units of finished products per month. At the same time, in order to meet the demands of all customers - not only large ones, but also small ones (especially Russian ones) - it is necessary to purchase an even more advanced and modern wide-format printing machine. This should provide an additional advantage in the difficult competitive struggle in the markets of the Customs Union. This aspect became the starting point for the enterprise's participation in the "One District - One Project" program.

- Buying such equipment is a very expensive pleasure. A new flexographic printing machine with the parameters we need costs about two million euros. Therefore, we immediately responded to the proposal of the district executive committee to include it in the pool of projects of the initiative and began to develop an investment project for the modernization of production, - the specialists continue to acquaint us with the technical capabilities of the enterprise. - After the project is approved, JSC "ASB Belarusbank" is ready to provide us with a loan of 5 million Belarusian rubles for a period of 10 years (another 2.5 million rubles are the enterprise's own funds). We expect that by the end of December the equipment will arrive in Nesvizh, in January we will begin adjustment. The new flexographic printing machine will be serviced by 8 print operators, the search and training of specialists for the created jobs has already begun.

If everything goes as planned, next year IOOO "Fleksoservice" will increase the volume of manufactured products by 25%. And the district will receive 8 new jobs with a salary of 3500 rubles, tax deductions to the budget will increase, as well as the share of exports in the structure of the enterprise's revenue.

- Needless to say, for medium-sized enterprises like us, with 67 employees, participation in the presidential initiative provides tangible advantages in the fight for export markets. The main one is a loan at an attractive rate with a repayment period of 10 years, - IOOO "Flexoservice" does not hide the advantages. - We expect that with the current profitability of our production, the project will pay for itself faster than in 10 years. And this is a good indicator.

Skim MILK

It is simply impossible to be in Nesvizh and not to drop in on the local baby food factory. This ultra-modern production facility, built from scratch on empty land in 2016, has been repeatedly named one of the best not only in the region, but also in the country. The investment volume at the time of launch was 95 million euros (40 million euros - bank loans, the rest - funds from Chinese investors). To say that this is a brand new factory is to say nothing: all processes here are maximally automated and computerized. Cleanliness - like in a laboratory. The huge enterprise, occupying 10 hectares of territory, is serviced by only 250 workers. How are things here today?

- We process 300 tons of milk per day, of which at least 92% is extra grade, the rest is premium grade. We produce whole milk products: cream, milk , kefir , drinking yoghurts, sour cream, softcottage cheese . 98% of the products are immediately exported, the remaining 2% are sold in the retail network of Belarus, - conducts a mini-tour director of OOO "Nesvizh Baby Food Plant" Vyacheslav Ivanov. Despite the fact that the plant is new and literally stuffed with the most modern technological solutions, modernization is carried out here on a systematic basis. In February, a new Swedish packaging line appeared here, which for the convenience of retail immediately packs finished products in corrugated cardboard. In addition to the six existing ones, 6 more tank tanks for storing milk (tanks) were purchased, which gives the enterprise maximum flexibility in planning and maneuver with production volumes. In March, the implementation of a five-year investment project for the development of new types of products worth 6.7 million rubles was completed here. Result: equipment for the production of fermented milk products was purchased and its range was expanded, 24 jobs were created, and the information technology department was modernized. - The design capacity of the plant is 500 tons of milk per day, so we definitely have room to grow. I will not hide the fact that there are already plans to increase export volumes. For example, it is possible to move the warehouse of raw materials and supplies outside the main building, and install new production lines in its place. But first, we need to clearly define which products to export, where to sell them and how to provide new volumes with raw materials. So in the future, we do not rule out the possibility of becoming part of the "One District - One Project" initiative, - says Vyacheslav Ivanov. - For a single region and the country as a whole, this is a very effective lever for developing territories and creating new jobs. Another huge plus is that this resource can be used by enterprises of various forms of ownership. Everyone is in absolutely equal conditions.

DIRECT SPEECH

Igor KUDRUK, Deputy Chairman of the Nesvizh District Executive Committee:

- At the moment, we have two investment projects in the implementation stage: the Foreign Unitary Enterprise Med-Interplast and IOOO Flexoservice. The first will begin production of finished products this year, the second - in 2026. In total, the district will receive more than 80 new jobs, I emphasize, high-tech and well-paid. In general, in the first half of the year, the Nesvizh district has seen a 30% increase (more than 140 million rubles) in investments in fixed assets. Particularly attractive to investors today are enterprises engaged in pharmaceutical, food and logging activities.

As for the "One District - One Project" initiative, we can safely say that this form of state support has taken root and is gaining popularity. In the last few months alone, at least 2-3 heads of local enterprises have contacted the executive committee, who would like to receive a loan under the initiative and modernize their production.

What is the appeal of this large-scale project initiated by the HEAD of state? It is that small and medium-sized businesses of any form of ownership can receive financial support on very favorable terms. If you have an idea and desire, go ahead! It's simple: register on the website Regionalnaya initsiativa.bel, answer the questions, confirm your application, and submit it to the Ministry of Economy for consideration. We, for our part, will turn on the most favorable treatment and do everything to ensure that sensible proposals reach the Development Bank and are financed. This is precisely the appeal of the initiative, that everyone is interested in it: the enterprise and its staff, the district, the region, and ultimately the entire country.

Vasily MATVEEV

Photo by Tatyana MATUSEVICH